The trade of conventional machinist is one of the most in demand jobs in the Quebec manufacturing sector. Many students or people in training who want to find a job as soon as they graduate choose this trade.

In this article, the industrial mechanics experts at HARtech give you a complete picture of the machinist trade including job description, training and salary.

What is a conventional machinist?

Before you train as a machinist, it’s important to make sure you have the right profile for this profession. For example, a future conventional machinist must enjoy working with automated machines and be interested in their operation. They must also appreciate and demonstrate precision, efficiency and quality of work.

The work of the conventional machinist also requires knowledge of applied sciences as well as good manual and numerical skills. The best machinists have excellent vision and even the ability to use custom machinery design to produce 3D drafts and parts. They can sometimes even provide their expertise to industrial machine design teams.

What are the responsibilities and tasks of a machinist?

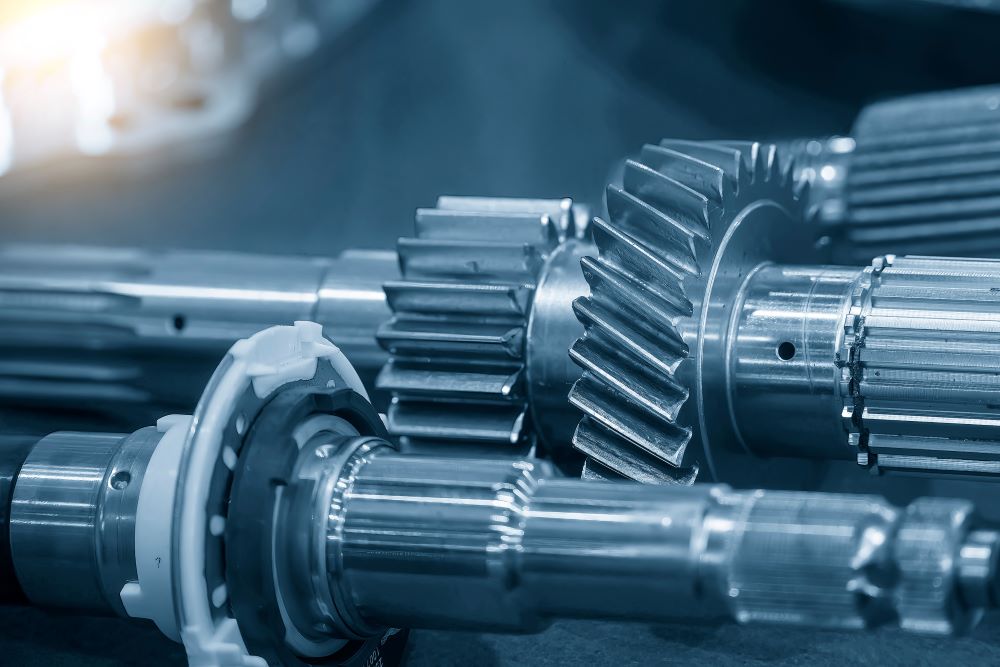

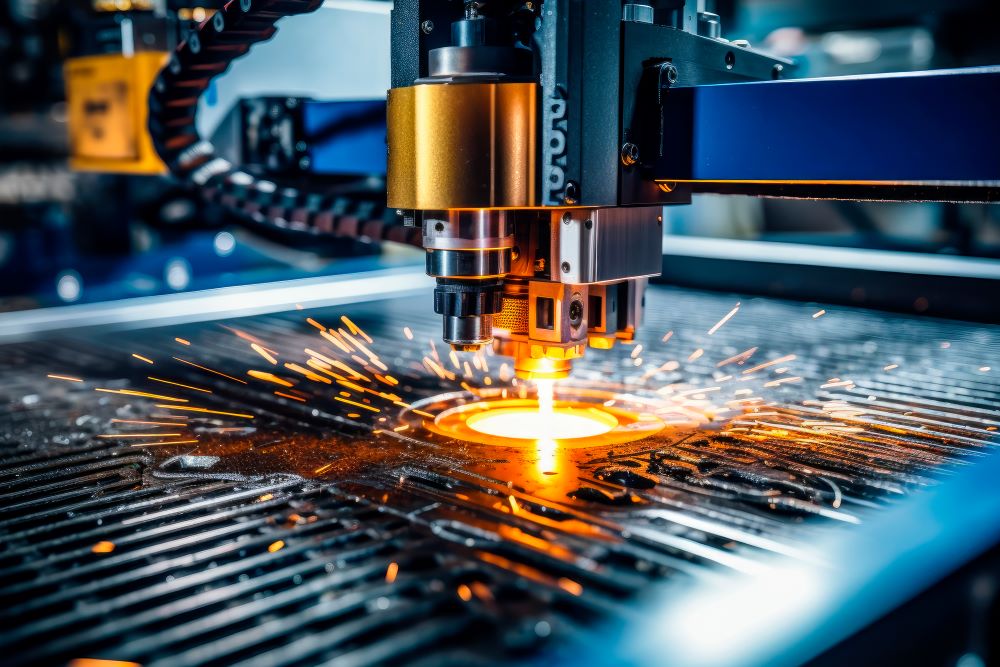

To perform their daily tasks, conventional machinists use machine tools to manufacture various mechanical parts. They use machines such as milling machines, drill presses and CNC lathes.

It is important for a machinist to understand the drawings and specifications of the parts being produced. They must regularly verify, using precision measuring instruments, that the dimensions of the parts they are machining are accurate and in accordance with any client requests.

Here are some tasks that are part of a typical day for a conventional machinist:

- Set up and operate conventional lathes, milling machines and drilling machines

- Control the quality of the parts

- Perform certain types of welding as required

- Interpreting drawings, calculations and verification of produced parts

How to become a conventional machinist

To become a conventional machinist, it is necessary to complete a Diploma of Vocational Studies (DVS) in machining techniques. This is an 1,800 hour program that can be taken at several vocational training centers. Usually, students enrolled in this DVS do an internship of about 120 hours in an industrial machine services shop near the end of their training.

If you want to become a specialized machinist, you must obtain an Attestation of Vocational Specialization (AVS) in machining on a numerically controlled machine tool after obtaining your DVS. This 885 hour program is offered in various regions of Quebec.

What is the salary for a conventional machinist?

The average salary for a conventional machinist job in Canada is $47,795 per year or $25 per hour. Those just entering the field earn about $43,875 per year, while those with the most experience earn up to $54,600 per year.

What skills and qualifications are needed for this trade?

The machinist trade requires certain natural abilities and skills to develop throughout training. Here are some examples of how to succeed in this industry:

- Experience on various conventional machine tools is necessary

- Demonstrate autonomy and independence

- Versatility and adaptability in environments

- Attention to detail and observational skills

- Reading and interpreting technical drawings to produce drafts

Want to work as a machinist at HARtech?

Now that you know a little more about this trade, why not start a career in Quebec? It takes a lot of time and hard work to achieve this goal, but it’s certainly worth it, as there are many job opportunities in this industry.

At HARtech, our conventional machinists apply the skills they learned during their training every day, in addition to those they have learned over the years. They also benefit from an ideal work environment and can use state-of-the-art equipment.

For more information, you can contact us or fill out the form on our career page.